A harness assembly typically uses sleeved wires and or multi conductor cables held together by ty wraps or tubing which protects and organizes the bundled wire cables.

Cable and wire harness assemblies.

By nature both wire harnesses and cable assemblies contain cables and wires.

Cable is an established and experienced wire harness and cable assembly manufacturer since 1985.

Tell us about your project.

The cables are bound together by a durable material such as rubber vinyl electrical tape conduit a weave of extruded string or a combination thereof.

Our cable assembly services support automotive medical communications agriculture general industry and any custom.

The main difference is in the engineering of the component to match the application.

Wire harness assemblies a wire harness also known as a cable harness or wiring assembly is a grouping of wires cables or subassemblies designed to transmit signals or electrical power.

Wire harnesses are low cost means with which to provide a bundle of cables and wires some degree of protection while keeping.

Most applications also require unique terminations like plug or socket arrangements attached to the wires.

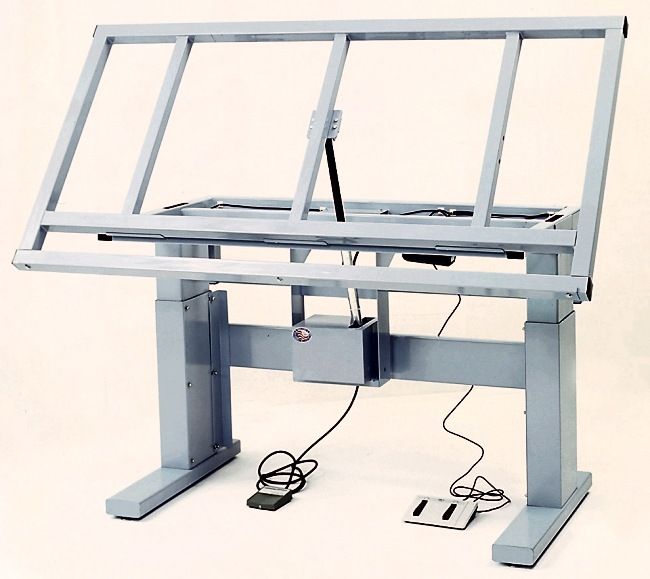

Rugged cable assemblies wire harnesses and control panels for use in the most harsh environments.

Cable has been a professional wiring harness manufacturer and has established a good relationship with world renowned vehicle manufacturers.

Temperature considerations from 50c to 150c push our engineering team to their limits but promark is always up to the challenge.

Why are wire harness cable assembly often confused.

We produce different customized automotive wiring harnesses and automotive cable assemblies for all types of vehicles.

A basic wire harness may include as few as three discreet components while the more classic harnesses include many more wires and other passive and.

We can quote customer requirements using the original parts called out on the customer s spec sheet such as molex jst amp te connectivity tyco lemo switchcraft etc or also using equivalent parts which usually save time and money.

Compatible cable can be your most valuable custom wire harness assembly partner.

Normal production run work is completed in 15 working days.

Our extensive expertise and manufacturing experience enable us to produce custom cables and wire harnesses assemblies that meet customer design needs and specifications.

Quick turn around cable assembly service reduces lead times for prototype of fast track requests to just three five days.